Seismic Design & Blast Protection Components

Gripple products has been utilised on an extensive number of high-profile job sites that include research labs, healthcare facilities, manufacturing plants, government & military sites, educational institutions, corporate offices, data centres and hotel/casinos including projects across Australia and New Zealand, for both new and retrofit installations.

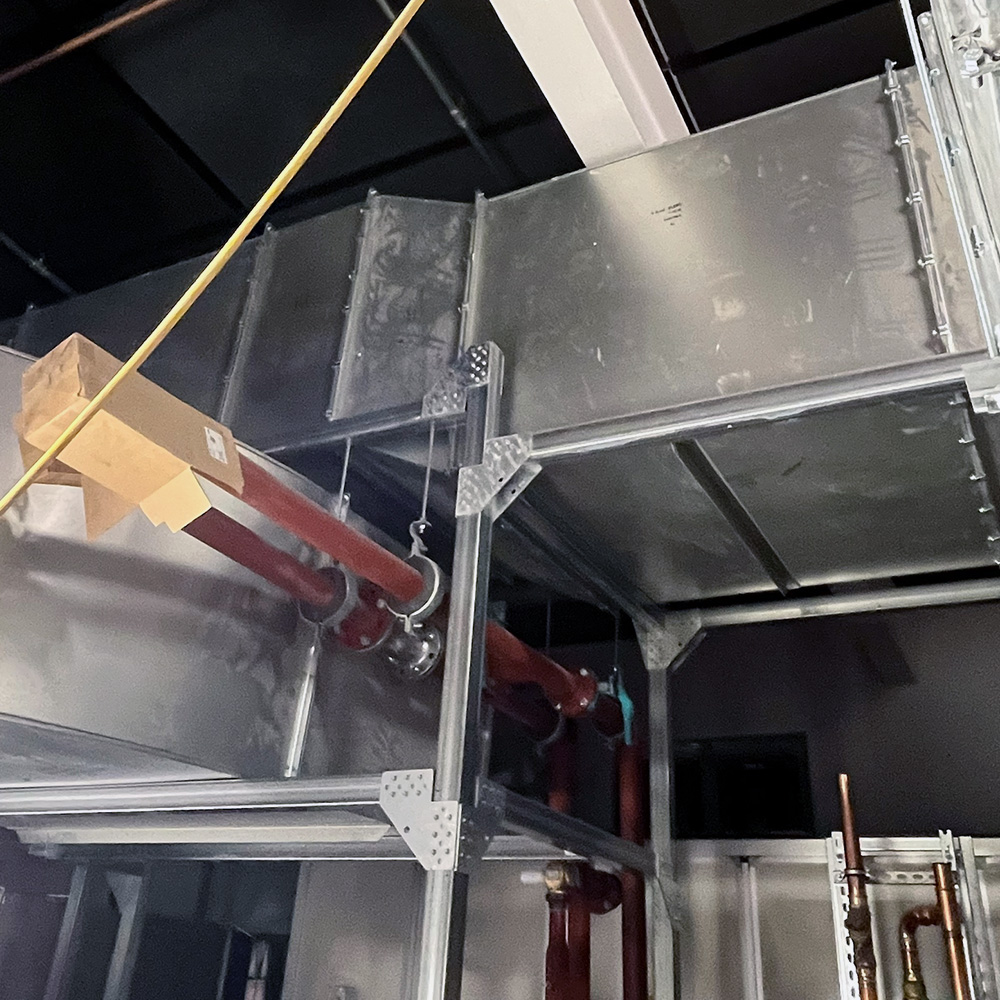

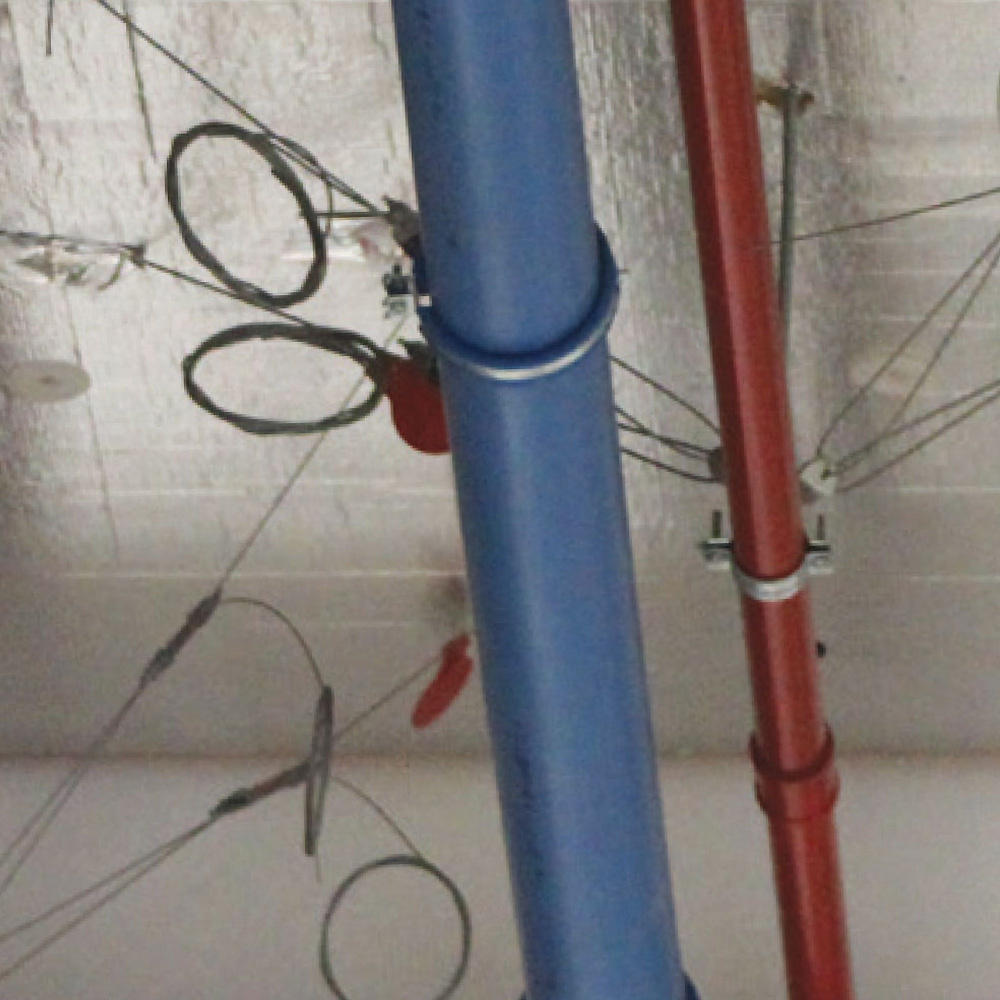

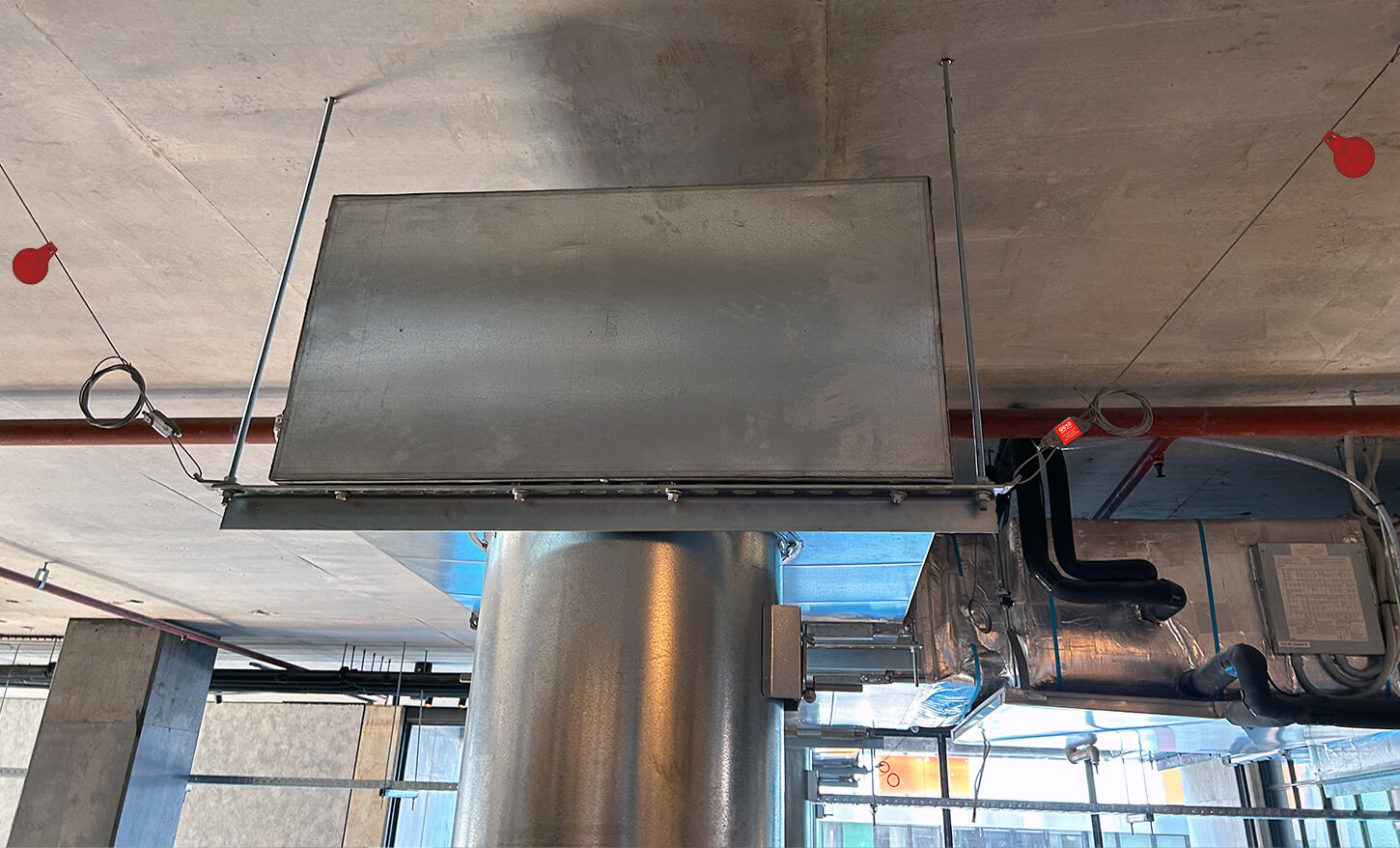

Gripple Seismic Bracing Systems are specifically designed and engineered to brace and secure suspended non-structural equipment (VAV boxes, fans, unit heaters, small in-line pumps, etc.) and components (HVAC duct, conduit/cable tray, and piping) within a building or structure to minimise damage from an earthquake or seismic event. Gripple ensures that the bracing meets the seismic design requirements of the non-structural components, in compliance with all relevant standards and specifications.

The types of MEP systems for which Gripple products can provide bracing & isolation solutions includes:

Seismic Bracing Installation Projects

At Gripple Australia, it is crucial to ensure that buildings and assets are properly protected and will continue to operate after a seismic event. We work with our clients to design and suspended non-structural building components are critical for the proper functioning of a building, and make up a high percentage of a building’s damage in a seismic event.

Our in-depth knowledge coupled with our experienced engineers allows us to deliver properly-engineered bracing solutions.

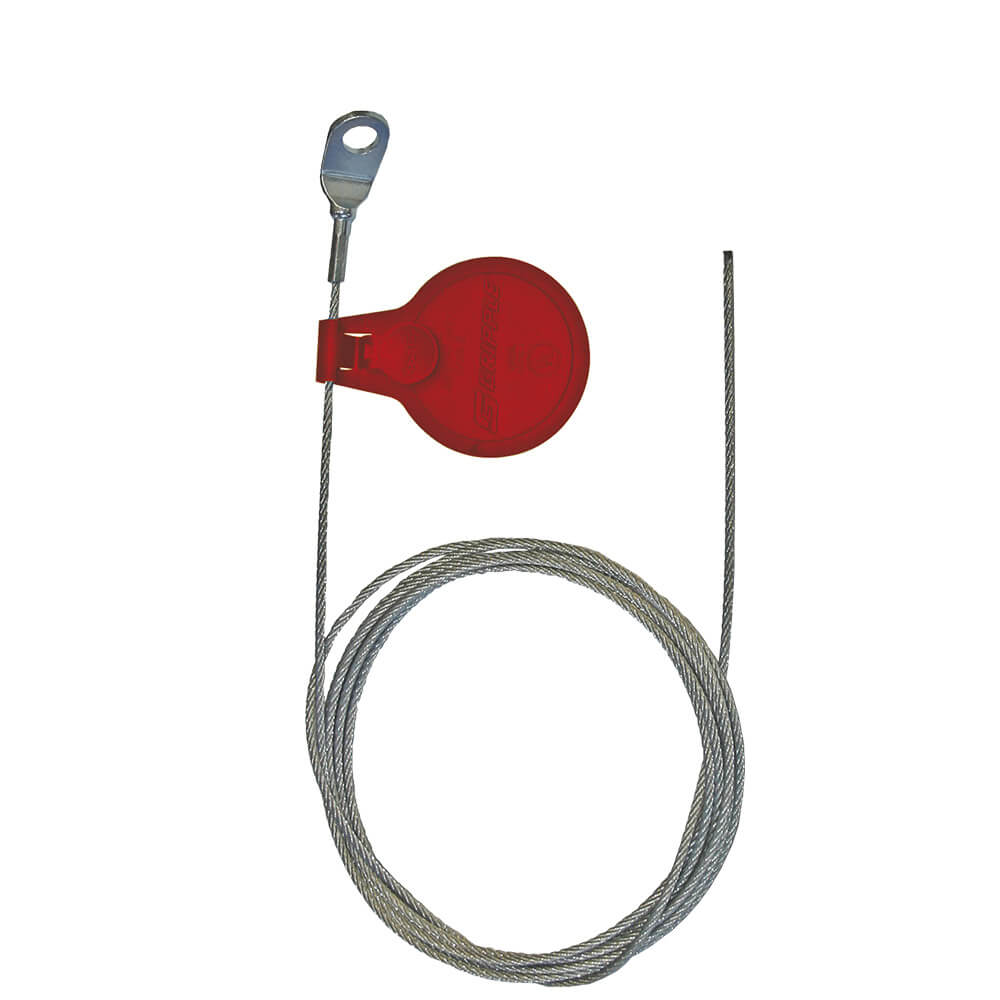

Seismic Bracing Products

Complete your project with one of Gripple’s most popular products, view the full Seismic Bracing range or please contact the Polyplas International Area Manager in your region.

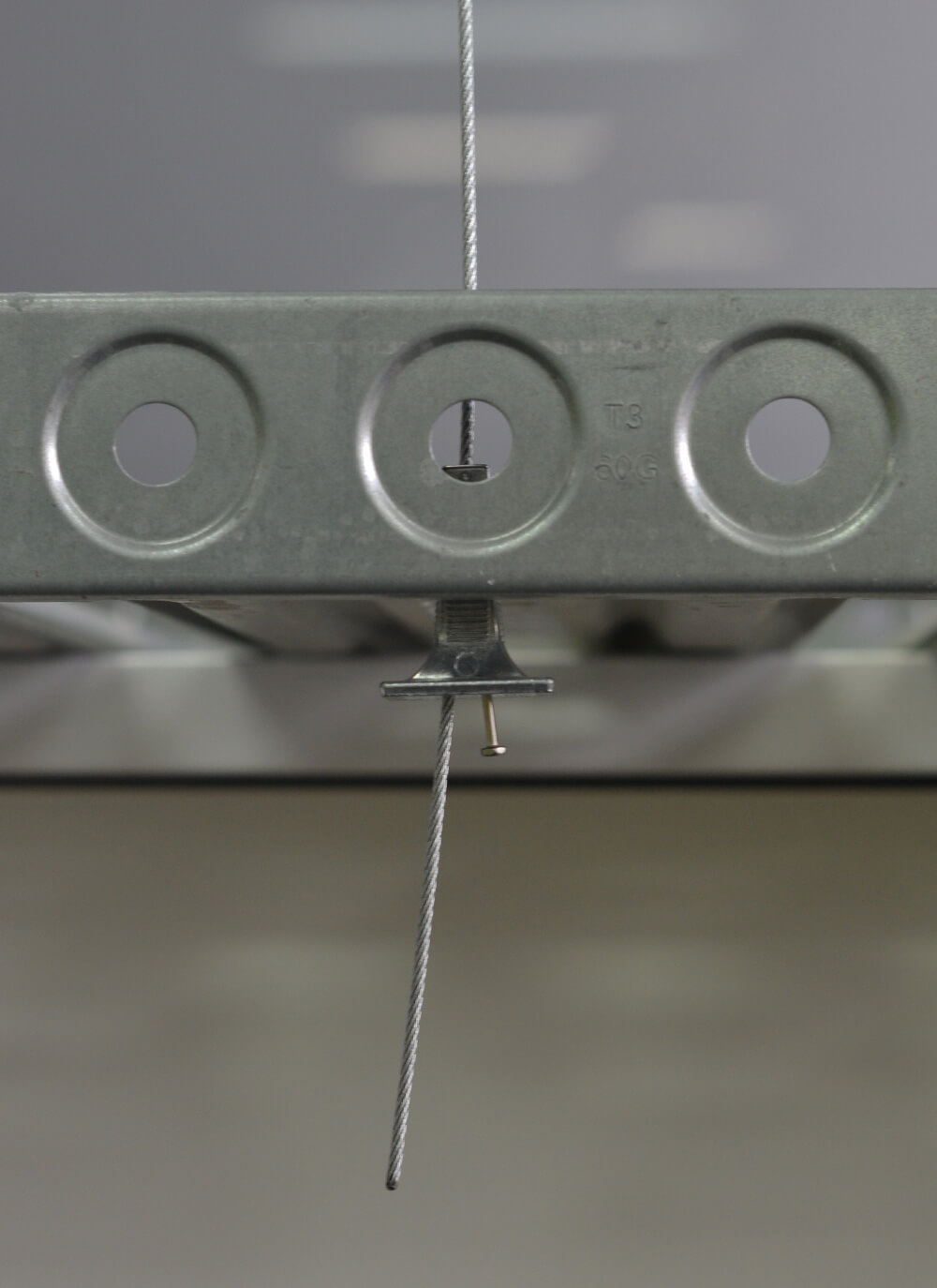

Seismic Bracing Anchors

Seismic Bracing End Brackets

Seismic Bracing Top Fitting

Why use Gripple?

Approvals & Certifications

Gripple holds the following industry approvals for our Wire Bracing Systems:

Seismic Bracing Articles

GS Bracing System Enhances Stability for Floor-Mounted Condensers

Gripple's GS Bracing system is designed with precision and resilience, it offers an effective solution…

Gripple GS10 Seismic Bracing – Secure Ductwork Installation

Gripple GS10 Seismic Bracing, a cutting-edge solution for securing ductwork in commercial and industrial settings…